When I entered the store, Tyler Brown and Stacey Stone were there to greet me and make me feel at home right away. I remember Stacey from J E Pistons and of course Tyler is a rookie sprint car driver. Stacey is Vice President of Sales and Marketing and Tyler is the parts Manager. You walk into the store where all kinds of supplies, parts, oils and other stuff is displayed and available for purchase. A brand new feel here, and everything was in order. The store was orderly and organized for racers to be able to find what they needed. The walk out in the shop showed much had been comlpleted since move-in day. Walking through the work areas of the shop, you see the mill machines, the CNC machine, the chassis jig, the motor room, the dyno and plenty of parts, chassis and motors completed. They said they are not totally moved in, but it looked fine to me and everyone was busy doing something.

The tour was very interesting to me as I saw a lot of different areas that the shop is going to support. The motor room and dyno room were real slick with some of the latest tricks to make a better product.

The shop is set-up for many things including building sprint cars, midgets and later street rods. In addition a lot of parts are manufactured here that would be considered bolt-ons. They are very close to being totally moved in, yet activity is going on all the time. I am sure the racers will be knocking the doors down to get their stuff soon. They are open for business and can be reached at 909-390-4686 to place an order or check stock on an item, or just schedule some work to be done, they are ready!

The ITI Performance office, store, warehouse and shop are all contained here at 800 So. Wineville Ave.

The long front of the building.

The store and entry is behind the single glass door.

The lighter colored part of the building to the left is where supplies arrive and parts and finished products go out.

The overhead door to the shop.

The parking lot.

Tyler Brown, right, and Stacey Stone greeted me. Stacey took me on the tour of the facility.

The counter with showcase items below it is neat.

The full counter.

The showcase for the many liquids needed in racing.

Parts, parts, parts.

A stand for rear ends.

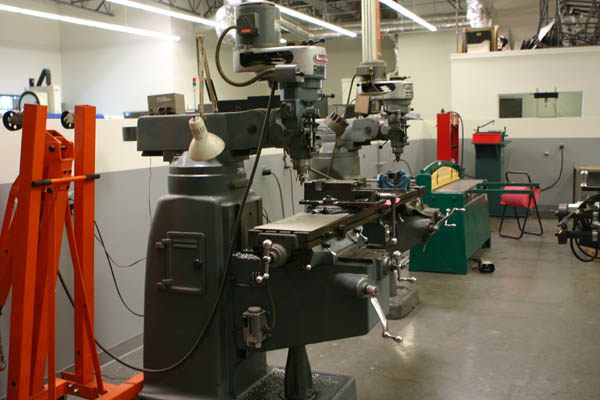

The tour in the shop starts with one of the many different kinds of machines. I am not going to name them, meaning I forgot their functions, but you smart ones will recognize them!

This one is colorful.

And there are two of them.

Some push bars, front and side bars are stock items already created, plus wheels are in stock shelves.

Various chassis are scattered around, some used and in for repair while others are ready to be shipped out.

Some smaller machines ready for use. Look at the chassis storage up in the rafters.

Here's Jerry creating a chassis on the jig. Jerry is from Boise, Idaho and loves his work. He said he got this opportunity to move here and build cars, and is a happy man! Jerry was so happy he whistled while he worked.

More work area.

Here is a completed car ready to go standing on end.

This is a look back at the shelves where the for sale products live.

This is Brad Downing's area, the motor room.

Brad poses with one of his engines. He has been building these bullets, oops that's a chassis isn't it? Well he had been building motors for over 30 years.

These are motors ready to go after refreshing or completion. Note the orange shipping crate.

The end motor looks brand new!

You can see the finished chassis stored above Brad's office.

The new dyno about to be put to good use. They will be able to reproduce the air intake that simulates when the motor runs at the track for better results.

Brad's office on the right and the motor room on the left and looking back to the chassis build area.

Now I've seen everything. An engine bag? You can dress up your motor?

The dyno control area.

Here is a fuel system dyno.

More equipment, but man powered in this case.

Another view back towards the jig.

And Jerry at work on the jig.

More machinery.

This is actually the car that David Cardey got up in the wall at the PAS a few weeks ago! It needs a new clip.

The parts room has shelving from floor to ceiling.

Tyler at his desk.

The lunch area.

This very nice model was made for Glenn and is about 3 feet long.

I was very impressed with the shop and expect a lot of racers will be too as they come to get stuff they need. It is kinda snakey to find back away from the freeway, but one trip should make it easy later. You can see the thought that went in the planning for the building and the layout. It looks like a good place to work with air-conditioning where needed. Drop in, they have everything you need for the care and feeding of a sprint car. I really enjoyed my time there and hopefully so will many racers as they come to shop.